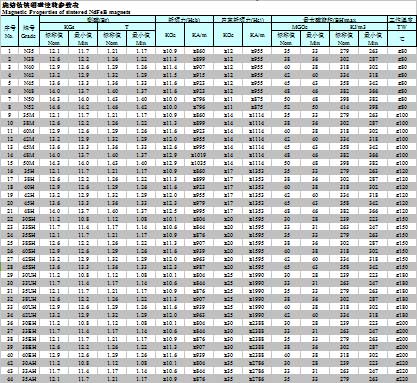

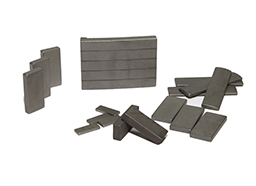

Sintered NdFeB magnet is rare-earth permanent-magnet materials with the strongest magnetic property in the world today. It is applied in various fields by the advantage of high Br, high Hcb and high energy density. It has become the indispensable functional materials of modern industry.

Aiming at "zero defect" of the products, we have established a strict quality management system. From new product development, process design, raw material procurement, production process control and product inspection to packaging, we are strict in line of the international quality management standard. Our company has gained ISO9001, TS16949 and other relevant certifications.

Hast

ICP

SEM

Magnetic-parameter-tester

Coating-thickness-test

Laser-particle-size-analyzer

SST-test

Oxygen-content-testing-instrument

Epoxy has good physical and chemical characteristics, excellent adhesion strength to the surface of metal and nonmetallic materials, good dielectric properties, variable shrinkage rate, good product dimensional stability, high hardness, good flexibility and stability for the alkali and most of the solvent .

Phosphating plays the role of basic protection of the magnets. It is anti-corrosion partially with almost none coating thickness. It can improve the adhesion of the film layer and anti-corrosion ability before plating .

Teflon has the characteristics of heat resistance (180 ~ 260 ℃), low temperature (-200 ℃) resistance and dielectric. Except for molten alkali metal, high temperature and difluoride, it can’t erode by other chemical substances. It has excellent weather resistance that its working life outdoor can be over 10 years generally. It also has low friction coefficience and good self-lubricating. In addition, it is almost no adhesive to other substances.

NiCuNi coating has excellent physical and chemical characteristics of anti-corrosion, hardness and abrasive resistance. When exposed to complex atmospheric environment, it can ensure the long-term stability and long service life of the appearance and the intrinsic performance. It is one of the most common coatings for NdFeB magnets.

Zn coating is generally thin and relatively good in corrosion resistance. It looks beautiful after coating. The "bone effect" is not obvious on the center and corner of magnet. The tolerance can also meet the tighter requirement. It can be used for short-term pollution discoloration in the limited corrosive mediators occasions.